For owners of heavy vehicles and commercial trucks, tyre maintenance is more than just a routine task. It is a critical safety requirement. Underinflated or overinflated tyres can cause blowouts, costly downtime, reduced fuel efficiency, and uneven tyre wear. This is where a tyre pressure monitoring system in Australia becomes important. A properly installed TPMS keeps your fleet operating safely and efficiently, protecting drivers, cargo, and vehicles.

In this guide, we will explore the essential features of TPMS for heavy vehicles, how they work, the types of sensors available, and whether investing in a system is worthwhile.

How does TPMS work?

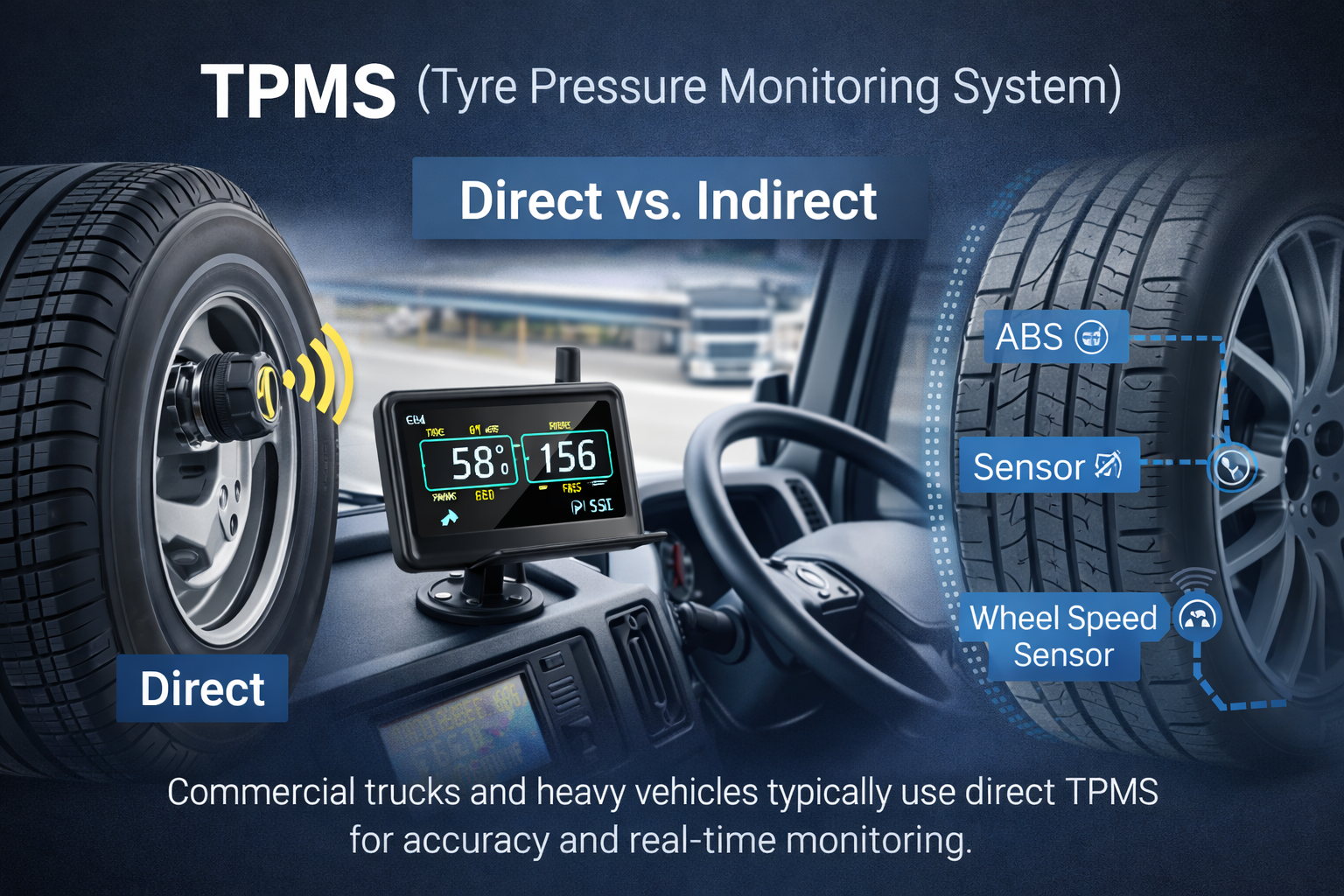

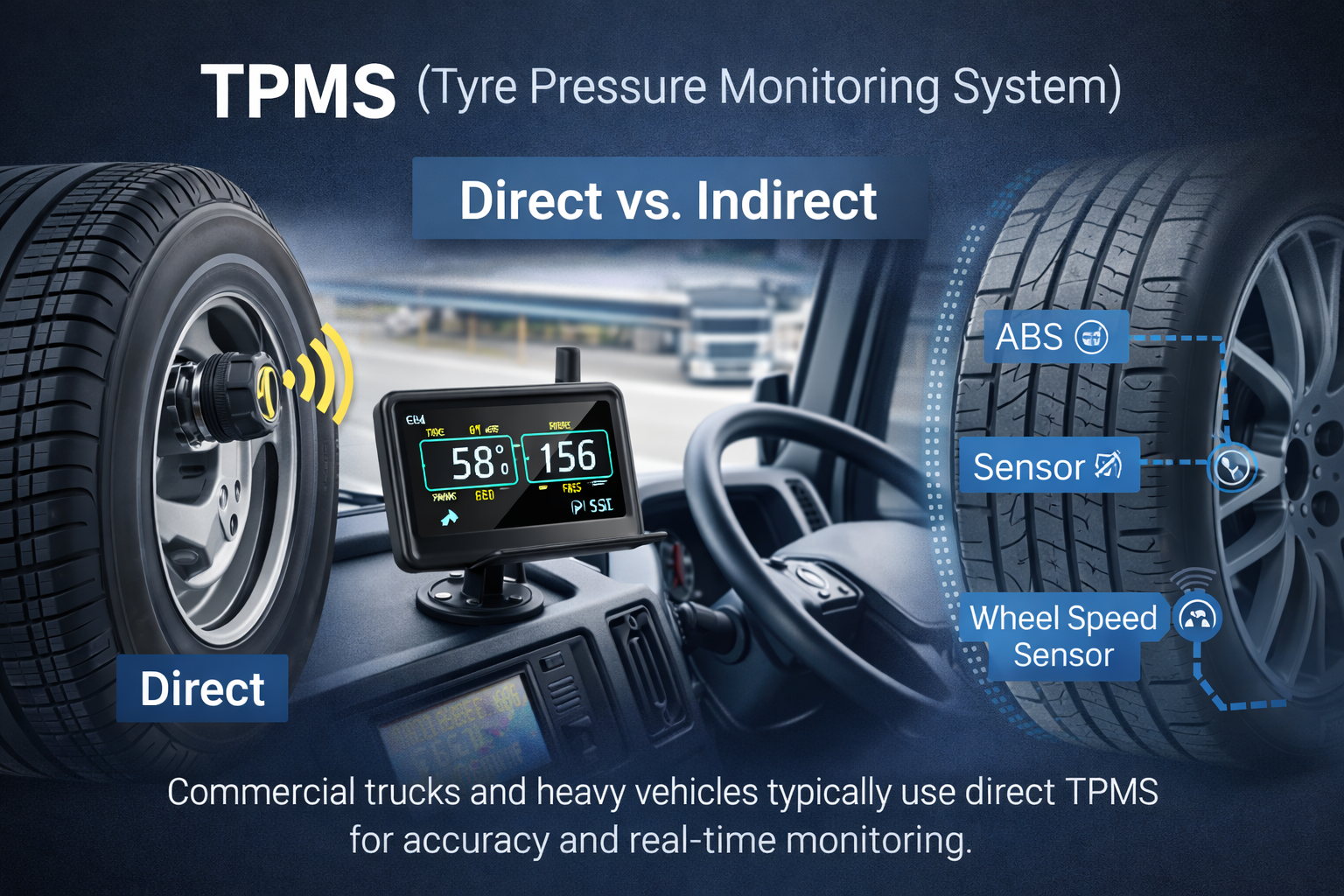

A TPMS (tyre pressure monitoring system) continuously checks the air pressure in your tyres and alerts the driver when there’s a significant drop or spike. There are generally two types of TPMS:

-

Direct TPMS uses sensors installed inside the tyre or on the valve stem to measure the actual tyre pressure. These sensors send data to a display inside the cabin.

-

Indirect TPMS relies on the ABS and wheel speed sensors to detect differences in wheel rotation, which can signal underinflation.

For commercial trucks and heavy vehicles, direct TPMS is preferred because it offers accuracy, real-time monitoring, and the ability to measure each tyre individually. Some systems can also track tyre temperature, which helps prevent overheating, a common cause of tyre failure in heavy-duty vehicles.

What’s the difference between TPMS sensors?

Not all TPMS sensors are the same. Choosing the right type is important for performance and durability. The most common variations include:

- High-pressure flow-thru sensors are suitable for heavy vehicles, trailers, and RVs. They can handle pressures up to 188 PSI and allow you to inflate tyres without removing the sensor.

- Low-pressure flow-thru sensors are designed for passenger vehicles and light commercial utes. They monitor pressures from 0 to 87 PSI. They can also inflate tyres without removing low-pressure flow-thru sensors.

- High-pressure external sensors mount on the valve stem and are ideal for heavy-duty commercial vehicles and trailers. They work well where pressures exceed 100 PSI and are often anti-theft for added security.

- Low-pressure external sensors are perfect for passenger vehicles, SUVs, and utes. They monitor pressures up to 87 PSI and are easy to install on the valve stem.

- External cap sensors are easy to install on the valve stem and are often anti-theft. They are best for retrofitting or fleets with frequent tyre changes.

- Internal sensors are installed inside the tyre. They offer maximum accuracy and protection from damage or theft.

Understanding these differences helps you choose a system that fits the pressure range and needs of your vehicle.

How do I know which TPMS sensor I need?

Choosing the right sensor depends on several factors:

- Vehicle type: Heavy trucks, trailers, and road trains need high-pressure sensors that can handle extreme loads. Passenger or light commercial vehicles usually use low-pressure sensors.

- Installation preference: Internal sensors provide accuracy but need tyre removal for installation. External sensors are easy to install but may be more prone to theft.

- Compatibility: Some TPMS monitors can work with different sensor types, offering flexibility for mixed fleets.

Check your vehicle manual or TPMS provider to ensure compatibility. In Australia, many fleets prefer TPMS tyre pressure monitoring systems that support high-pressure readings, multiple tyre monitoring, and mobile app connectivity.

What is the typical lifespan of a TPMS sensor?

A TPMS sensor’s lifespan varies based on the type of sensor, usage, and environmental conditions. Most sensors last between 5 and 10 years or 60,000 to 100,000 km. However, heavy-duty vehicles operating under extreme conditions may wear out faster.

Here are key factors that affect sensor longevity:

- Battery life: Many internal sensors have non-replaceable batteries that usually last 5 to 7 years. External sensors often use replaceable batteries and typically last around 1 to 2 years.

- Exposure: High heat, moisture, or corrosive road conditions can damage sensor components.

- Tyre changes: Frequent tyre rotations or replacements may need sensor recalibration.

Regular maintenance and monitoring help ensure your TPMS keeps providing reliable data throughout its life.

Is it worth getting TPMS?

Investing in a TPMS in Australia for commercial trucks and heavy vehicles is not just a convenience; it’s a safety and cost-saving measure. Benefits include:

- Better safety: Real-time alerts for underinflated, overinflated, or overheating tyres cut down the risk of blowouts.

- Improved fuel efficiency: Keeping tyre pressure at the right level reduces rolling resistance, saving fuel on long-haul trips.

- Longer tyre life: Even wear lowers replacement costs and downtime.

- Enhanced safety: Continuous monitoring helps prevent sudden tyre failures and reduces the risk of road accidents.

- Improved fuel efficiency: Properly inflated tyres minimise drag, helping fleets lower overall fuel expenses.

- Extended tyre life: Maintaining optimal pressure reduces uneven tread wear and maximises tyre lifespan.

- Better vehicle handling: Correct tyre pressure improves stability, steering response, and overall driving control.

- Convenience and maintenance: Easy-to-read pressure data allows quicker inspections and proactive maintenance planning.

For operators looking for the best TPMS, systems with high-pressure flow-thru sensors, large LCD displays, multiple alarm modes, and compatibility with heavy-duty trailers are ideal. Some advanced monitors can track up to 76 tyres, making them suitable for multi-trailer road trains and large fleet operations.

Key TPMS Features to Look For

When choosing a TPMS for your commercial vehicle, keep these features in mind:

Real-time monitoring: Get accurate tyre pressure and temperature data for each tyre.

- High/low-pressure alarms: Alerts for abnormal tyre conditions can prevent dangerous situations.

- Fast leakage detection: Receive immediate warnings if a tyre loses pressure quickly.

- Battery status alert: This makes sure sensors stay functional, which is especially important for fleets.

- Easy installation and programming: Plug-and-play options cut down on downtime during retrofitting.

- Wide sensor compatibility: This allows use across different vehicles and trailers.

- Durability: Look for high-pressure and anti-theft external sensors designed for heavy-duty use.

A high-quality TPMS isn’t just a gadget; it’s essential for safety and efficiency in operations.

Tyre Pressure Insights for Truck Owners

For heavy vehicle and commercial truck owners, a TPMS is no longer a luxury. It’s an essential safety tool. Understanding how TPMS works, the types of sensors available, and their lifespan can help you make informed decisions for your fleet. With proper tyre monitoring, real-time alerts, and reliable sensor performance, you can reduce downtime, improve fuel efficiency, and prevent costly accidents.

Whether you operate a single truck or manage a fleet of long combination vehicles, investing in the best TPMS for your needs is a wise choice for long-term safety and operational efficiency.

Did you enjoy reading this article?

Stay updated on our latest deals and promos by following our social media accounts.

Find this article helpful? Don't forget to click on the share buttons below.